Lithium Bromide Absorption Chiller for waste heat recovery

โพสต์เมื่อ 3 ปีที่แล้ว

รายละเอียด

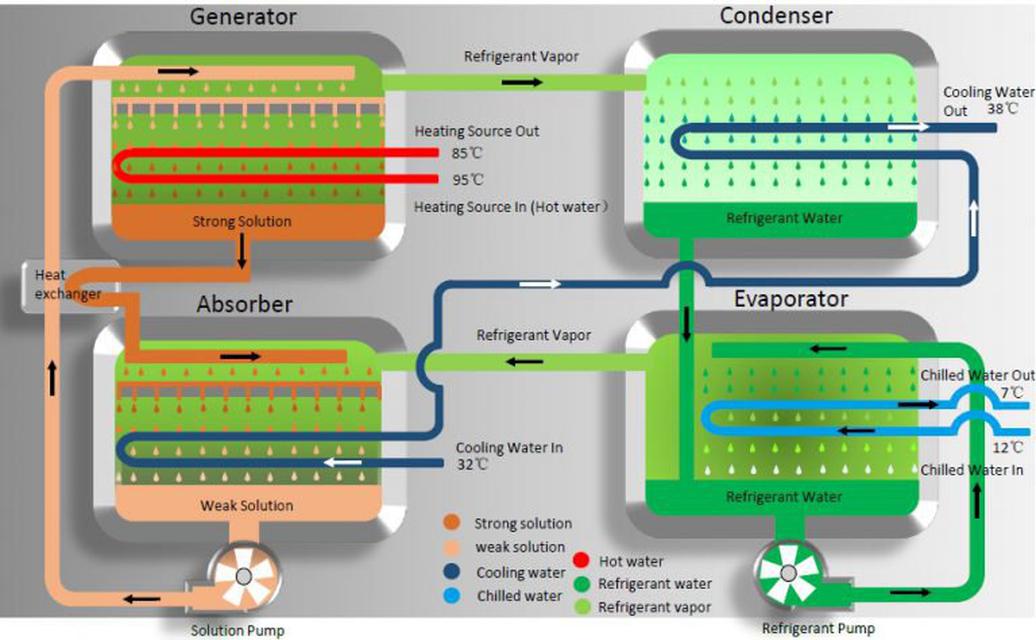

Lithium Bromide Absorption Chiller for waste heat recovery Absorption Chiller is an equipment which uses heat source from natural gas ,diesel, solar energy and waste heat to produce a cooling system. As its practical function, absorption chiller is normally installed in air-conditioning building such as factory, office, hospital or airport. Especially, the machine utilize the waste heat recovery from gas engine or gas turbine. Although the electricity is in limited situation, absorption chiller also can activate. Furthermore, it only consumes a small amount of electric energy in the systems, compared to electric chillers. During the process, the absorption chiller uses a lithium bromide solution (LiBr) as the absorbent and water as the refrigerant. The reason a lithium bromide because of not being a hazardous chemical. Another outstanding characteristic is non-CFCs and non-HFCs which are harmful to the environment. Here are more advantages of Absorption chiller: Driving power from Heat Energy, Less electric energy consumption, Easy maintenance, Low maintenance costs, Less noise and vibration, Non-CFCs or Non-HFCs refrigerant and Environmental-friendly. Principle Firstly, weak solution in the absorber which is suitable for concentration mixed with lithium bromide solution and water is pumped through the heat exchanger. Then, It becomes the intermediate solution before flowing into the generator separating the water and lithium bromide solution. The generator utilizes the heat energy from waste heat such as Flue gas, Steam or Hot water. In the Generator, the water will be changed to vapor and leave the lithium bromide solution, but it will not be left as a waste. It will be formed as a liquid and drop to bottom of the generator. The liquid flows down to preheat the weak solution in the heat exchanger and becomes strong solution. Then, it flows back to spray over the absorber to absorb the vapor for next process again. Meanwhile, the vapor which left from lithium bromide solution in generator flows into the condenser. The solution will be cooldown by the cooling water, then it will be condensate to the refrigerant. It flows down to the evaporator due to the vacuum condition which made the water boiling temperature becomes low. In the Evaporator, 12°C chilled water which returns from operation system flows into the evaporator. The unwanted thermal energy will be extracted by spraying refrigerant over the chilled water pipe in the evaporator. Therefore, the chilled water temperature will be decreased to 7°C. Finally, after the refrigerant water extracted unwanted thermal from chilled water, it will become the vapor again as low boiling temperature under the vacuum condition in the evaporator. After that, the vapor will be absorbed by strong solution and become weak solution for the new cycle again. Shuangliang Waste Heat Recovery Solution Provider Shuangliang has dedicated to the study of industrial waste heat recovery over 3 decades. As endless attempt, Shuangliang is gradually developing from as equipment supplier into a system provider. About 60% of all energy generated in the world is left as a waste heat. Unfortunately, most of the waste heat will be degraded as traditional heat recovery technologies can’t activate effectively. From this point, Shuangliang Eco-Energy System Co., Ltd. wants to solve this problem by turning it to useable energy. Shuangliang Eco-Energy Systems Co., Ltd. has been founded since 1982. According to the expertise, it is the first and only listed company in the absorption chiller industry. Eventually, the company joined with Shuangliang Group, a large enterprise that provides manufacturing, chemical and materials, and hotel services. Product - Flue Gas Lithium Bromide Absorption Chiller Flue gas absorption chiller is applied as an important role of the tri-generation system. Normally, gas engine produces electricity while exhaust heat drives an energy of absorption chiller. According to this process, the waste heat from gas engine can provide cooling capacity for any communities and buildings. As a combination of cooling, heating, and power generation system, the flue gas absorption chiller can increase capacity utilization and efficiency up to 85%. Moreover, the absorption chiller enhances power supply safety from the grid and leads more electricity saving. From several advantages, the absorption chiller can enhance environmental protection and sustainably economic development. - Direct Fired Lithium Bromide Absorption Chiller Due to the increase of electricity price and continual concern to environmental issues, Shuangliang eco-energy develops the high energy-efficiency. Absorption chiller is energized by the heat from directly burning light oil, heavy oil, industrial gas, or natural gas. By using heat of different levels, the direct fired absorption chiller can produce chilled water temperature from 5 °C to 7 °C which mostly used in the air conditioning system. - Steam Lithium Bromide Absorption Chiller The Steam Lithium Bromide Absorption chiller is one of Shuangliang famous models. Steam pressure with 0.01-0.15 MPa can provide a cooling capacity of 350~11630 kW. Also, 5°C to 7°C chilled water is suitable for the central air conditioning system or industrial process. Due to its advantage, waste steam from the steam turbine in power generation can be reused as an energy for absorption chiller, also steam from the boiler Especially, Shuangliang double-effect absorption chiller is in the most leading manufacturer. With high COPs of 1.43, it can provide high efficiency, low energy consumption and low-operating costs. - Hot Water Lithium Bromide Absorption Chiller With Shuangliang standard specifications, the temperature range of hot water about 90°-130°C is applied as a main role of the hot water single stage and two-stage absorption chillers. Moreover, Shuangliang standard specifications are available for suitable temperature and customer’s requirement. The cooling capacity of hot water absorption chiller is between 350~6890 kW. As the chilled water temperature is about 5 °C –7 °C which is useful for air conditioning system and industrial process. To reuse waste heat recovery, utilizing waste hot water from gas engine or other industrial process in hot water absorption chiller is one of effective ways to save energy, reduce electricity cost and saves considerable amount of operating costs. https://www.gmsthailand.com/product/lithium-bromide-absorption-chiller/

อ่านเพิ่มเติม